2022… It was the beginning of a challenging year for AYVEN Group. Our warehouses were overflowing, customers constantly complained about delayed orders, and our operations were becoming increasingly costly. To be honest, even we didn’t know where we were heading. That’s when we came across the concept of lean transformation. At first, we wondered, “Does this really work?” But in the end, we realized we had no choice but to give it a try—and so we rolled up our sleeves. We had no idea that small changes could make a huge difference… until we immersed ourselves in the process!

AYVEN Group is a company with an extensive distribution network operating in Uzbekistan. Under the leadership of Mr. Vali (CEO), different departments of the company worked in harmony throughout this transformation process. Due to efficiency issues and high operational costs, the company launched its Lean Transformation Project in 2022. The project aimed to reduce costs, improve customer satisfaction, and enhance employee engagement by optimizing operational processes.

This document outlines the entire journey of AYVEN Group’s Lean Transformation Project—from its initial stages to final outcomes—along with key takeaways. Additionally, it provides a comprehensive evaluation backed by raw data insights.

Company Information & Current Situation Analysis

General Information About AYVEN Group

| Number of Employees: | 700+ |

| Sales Team: | 450 employees |

| Back Office: | 250 employees (Warehouse: 50, Distribution: 50, Office: 60) |

| Branches: | 13 |

| Warehouses: | 13 |

| Tashkent Office: | 400+ square meters |

| Fleet: | 30-40 vehicles in Tashkent, 20+ vehicles outside Tashkent |

Current Situation Analysis

Key Challenges Before the Project:

- Excess inventory and high costs: Storage costs were continuously increasing, and surplus stock negatively impacted profitability.

- Low efficiency: Employees were losing time due to undefined processes. Order processing mistakes and operational errors were on the rise.

- Customer satisfaction issues: Delayed deliveries and order errors led to an increase in customer complaints.

- Lack of digitalization in finance and accounting processes: All transactions were handled manually. Losing documents and spending hours searching for simple data had become an almost routine problem.

The exhaustion on our employees’ faces made it clear—something had to change. It was time to take action.

Finance and Accounting Processes

Before the project, AYVEN Group faced several inefficiencies in its finance and accounting processes. Excessive personnel usage, manual workflows, and a lack of digitalization caused delays in operations. As part of the lean transformation, Kaizen practices were integrated into the finance team under the leadership of Azaljon Turdaliev (CFO) to improve efficiency.

Key Challenges Before the Project:

- Excess inventory and high costs: Storage costs were continuously increasing, and surplus stock negatively impacted profitability.

- Low efficiency: The lack of clearly defined processes led to time loss and unnecessary workloads for employees.

- Customer satisfaction issues: Delayed deliveries and order errors resulted in increased customer complaints.

What Did We Achieve in This Project?

- Reduced the number of warehouse employees from 50 to 34.

- Reduced the number of vehicles from 41 to 27.

- Increased digitalization in finance and accounting processes.

- Reduced delivery time by 25%.

- Improved workforce efficiency by 30%.

- Decreased customer complaints by 15%.

- Optimized warehouse and inventory management.

Lean Tools and Approaches Implemented

1. Value Stream Mapping

To identify waste in order-picking and distribution processes, the Value Stream Mapping method was applied under the leadership of Murodjon Khamidullaev (Kaizen Office Manager).

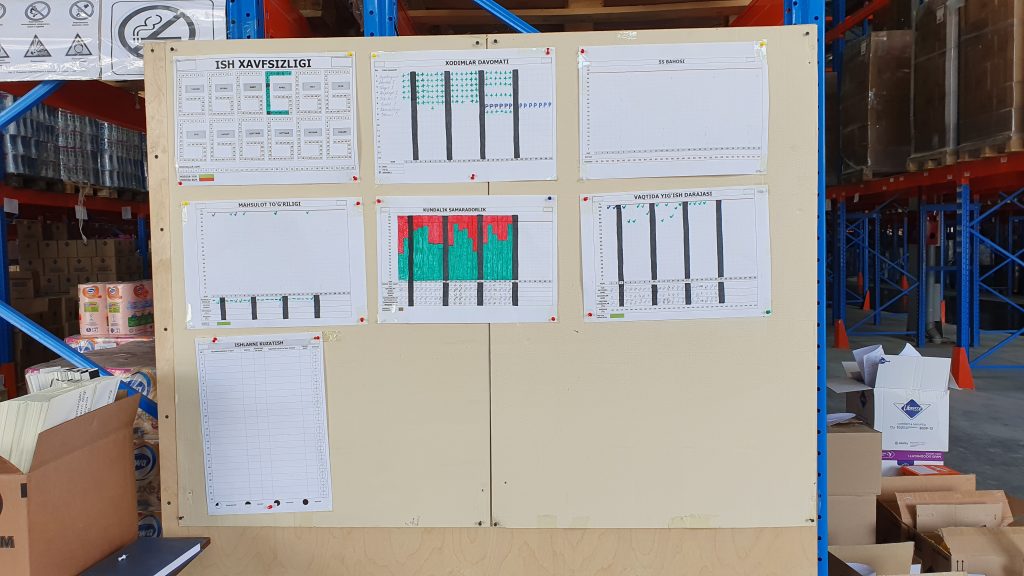

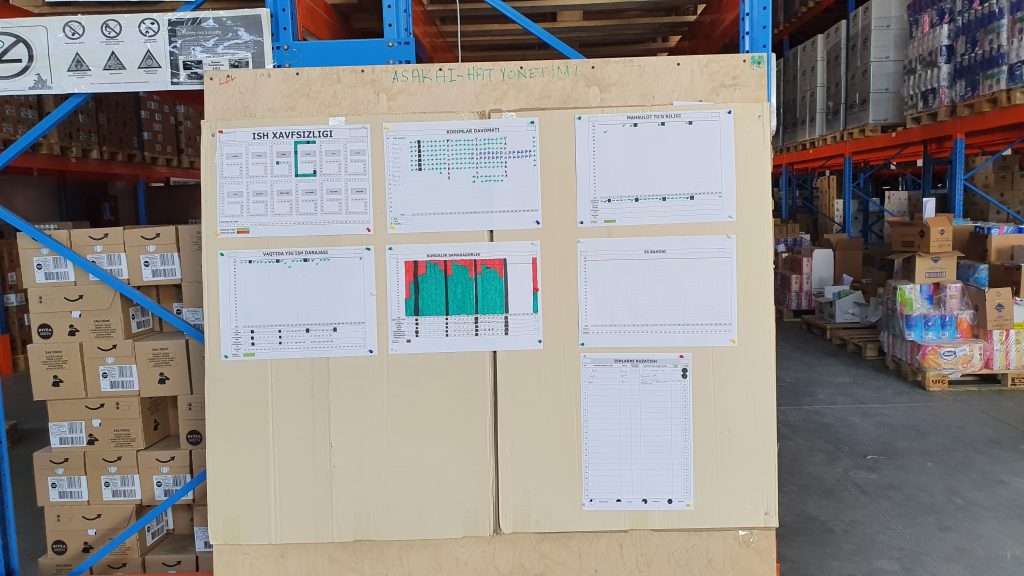

2. 5S System

By organizing and standardizing warehouse and office spaces, workplace efficiency was significantly improved.

3. Kanban System

To ensure visual control in inventory management, the Kanban system was implemented under the supervision of Jurabek Ashurov (Head of Warehouses). This made order processes more systematic and efficient, ultimately reducing delivery times.

4. Route Optimization

To enhance the efficiency of distribution processes, route optimization was conducted. As a result: Vehicle load capacity was increased.

Delivery times were reduced.

Outsourced operations were brought in-house, and new projects were introduced to lower operational costs.

To enhance the efficiency of distribution processes, route optimization was conducted. As a result:

Results Achieved: Major Gains

The dedication and effort of our team in this project were truly remarkable! Here are our biggest achievements:

✔ We freed up space in our warehouses: Storage costs were reduced by 25%, eliminating unnecessary stockpiles!

✔ Faster deliveries: Order fulfillment times were reduced by 30% thanks to route optimization.

✔ Fewer customer complaints: By preventing errors and delays, customer satisfaction increased by 50%!

✔ Increased operational efficiency: The number of warehouse staff was reduced from 50 to 34, allowing us to accomplish more with fewer resources!

✔ Optimized vehicle usage: The fleet was downsized from 41 to 27 vehicles, significantly reducing distribution costs!

| KPI | Before | After | Improvement (%) |

| Storage Costs | High | Reduced by 25% | -25% |

| Delivery Time | Long | Reduced by 30% | -30% |

| Customer Complaints | High | Reduced by 50% | -50% |

| Warehouse Staff | 50 | 34 | -32% |

| Fleet Size | 41 Vehicles | 27 Vehicles | -34% |

The results of this project exceeded our expectations, and our team’s hard work truly deserves recognition!

- Storage Costs Reduced by 25%: Excess inventory and unnecessary stock expenses were optimized.

- Delivery Times Cut by 30%: Distribution processes became more efficient through route optimization.

- 50% Reduction in Customer Complaints: Fewer errors and delays led to higher customer satisfaction.

Everyone’s Ideas Were Considered

Throughout this process, we valued every idea from our team. Cezmi Aytekin (Lean Project Leader) encouraged employee participation, ensuring that suggestions were implemented. During Kaizen meetings, everyone shared their insights, contributing to process improvements. For example, one of our warehouse workers suggested a small adjustment in the order-picking area, which significantly reduced processing time!

During one of the meetings, someone asked, “Wouldn’t it be faster if we collected orders using wheeled baskets?” At first, it seemed like a simple idea, but we tested it

and the results were incredible! We also implemented improvements that reduced both the number of checks and the time required for them. As a result, our daily processing time was nearly cut in half. That’s the power of lean thinking!

Small Changes, Big Transformations

As consultants, we are extremely pleased with how Jurabek Ashurov (Warehouse General Manager) and Murodjon Khamidullaev (Kaizen Office Manager) have evolved into a highly effective transformation team. Under their leadership, major improvements were made, and team motivation soared.

✔ Small changes led to big results! Thanks to Kaizen practices, our processes experienced a revolutionary transformation. A simple checklist added to the goods-receiving process reduced error rates by 40%.

✔ Lean processes powered by technology: By digitizing operations, we reduced manual workload and accelerated both accounting and warehouse processes. Salih Temurcu (IT Systems Manager) led the implementation of new systems and improvements to existing ones.

✔ Team spirit: Our employees are no longer just completing tasks—they take ownership of the process. Everyone proudly says, “I contributed too!” and adds more value to their work.

- The Importance of Building a Culture of Change: Ensuring active employee participation in the process is of great importance.

- Data-Driven Decisions: Regular data analysis in process improvements has led to successful results.

- Even small adjustments have led to massive transformations—thanks to Kaizen! For example, a simple checklist added to the goods-receiving process significantly reduced the error rate.

- Utilizing Technology and Digital Tools: Process improvements have been accelerated through digital solutions.

Journey to a Lean Future

With the Lean Specialists trained at the Kaizen Office, we have now started implementing lean practices in other subsidiaries as well. The first results are coming in, and this transformation is spreading like ripples in a pond. Our experienced team members apply their knowledge to different operations, contributing to AYVEN Group’s overall efficiency.

But this journey doesn’t end here! At AYVEN Group, we are not limiting lean transformation to just warehouse and logistics. Mahmud Nasrollayev (Project Coordinator) has been ensuring team coordination at every stage of the process. We will extend lean principles to accounting, finance, human resources, procurement, and even IT!

So, what’s next? We aim to support lean processes with new technologies, integrate more employee suggestions, and become a leader in industry-wide transformation. Efficiency is no longer just a goal—it has become an integral part of our work culture!

AYVEN Group is committed to taking lean transformation to the next level. In the coming period, we plan to integrate lean production principles into IT and sales processes, ensuring continuous improvement across all operations. With digitalization, we will enhance lean management through process automation and data analytics. Additionally, by sharing knowledge with other companies, we aim to lead sustainable transformation in the industry.

This journey is far from over! At AYVEN Group, we are determined to push lean transformation even further. We will continue supporting lean processes with new technologies, encouraging more employee-driven ideas, and leading transformation across the industry.