In today’s competitive business world, companies need to increase efficiency, reduce costs and increase productivity. This is exactly where Lean Manufacturing comes into play. This powerful method, which enables companies to gain a competitive advantage by optimizing production processes and eliminating waste, offers great opportunities, especially for production managers and engineers: Creating more value with fewer resources! Every company that wants to succeed in the global market needs to understand and implement the solutions offered by lean manufacturing.

The Birth of Lean Manufacturing: Toyota Production System

The concept of Lean Manufacturing emerged in the 1950s with the development of the Toyota Production System (TPS) by Toyota engineers Eiji Toyoda and Taiichi Ohno. After studying Ford’s factories in the U.S., Eiji Toyoda realized that mass production was not suitable for Japan. The small size of the Japanese market, the diversity of customer demands, and limited capital accumulation made it challenging to adapt Ford’s large-scale production model to Japanese industry. Therefore, it was necessary to develop a more flexible production system that could achieve higher efficiency with fewer resources.

Taiichi Ohno brought this idea to life by creating the Toyota Production System (TPS). The primary goal of TPS was to achieve the most efficient production model by eliminating waste (muda), overburden (muri), and unevenness (mura) in production processes. The development of this system introduced key lean manufacturing principles such as the Kanban pull system, Just-in-Time (JIT) production, error prevention (Poka-Yoke), and continuous improvement (Kaizen).

Transition from Mass Production to Lean Manufacturing

Compared to traditional mass production, lean manufacturing offers a more flexible, efficient, and customer-focused approach. Here are the key differences:

| Feature | Mass Production | Lean Manufacturing |

|---|---|---|

| Production Approach | Production in large batches | Demand-driven production (pull system) |

| Inventory Management | High inventory levels | Minimum inventory (Just-in-Time – JIT) |

| Waste (Muda) | Overproduction, excessive transport, waiting | Minimization of waste |

| Flexibility | Low | High |

| Quality Management | Errors corrected at the end of production | Errors detected immediately (Poka-Yoke) |

| Employee Involvement | Workers perform specific tasks only | Workers involved in problem-solving (Kaizen) |

| Delivery Time | Long | Short |

Thanks to these differences, lean manufacturing provides companies with a more efficient and customer-centric structure, offering a significant competitive advantage.

Core Elements of Lean Manufacturing

Lean Manufacturing is a production philosophy that originated from the Toyota Production System (TPS) and is now widely used across various industries. Its goal is to eliminate all processes that do not add value to the customer, making production workflows smoother and more efficient. The lean approach aims to produce the right product, at the right time, in the right quantity, with minimal waste.

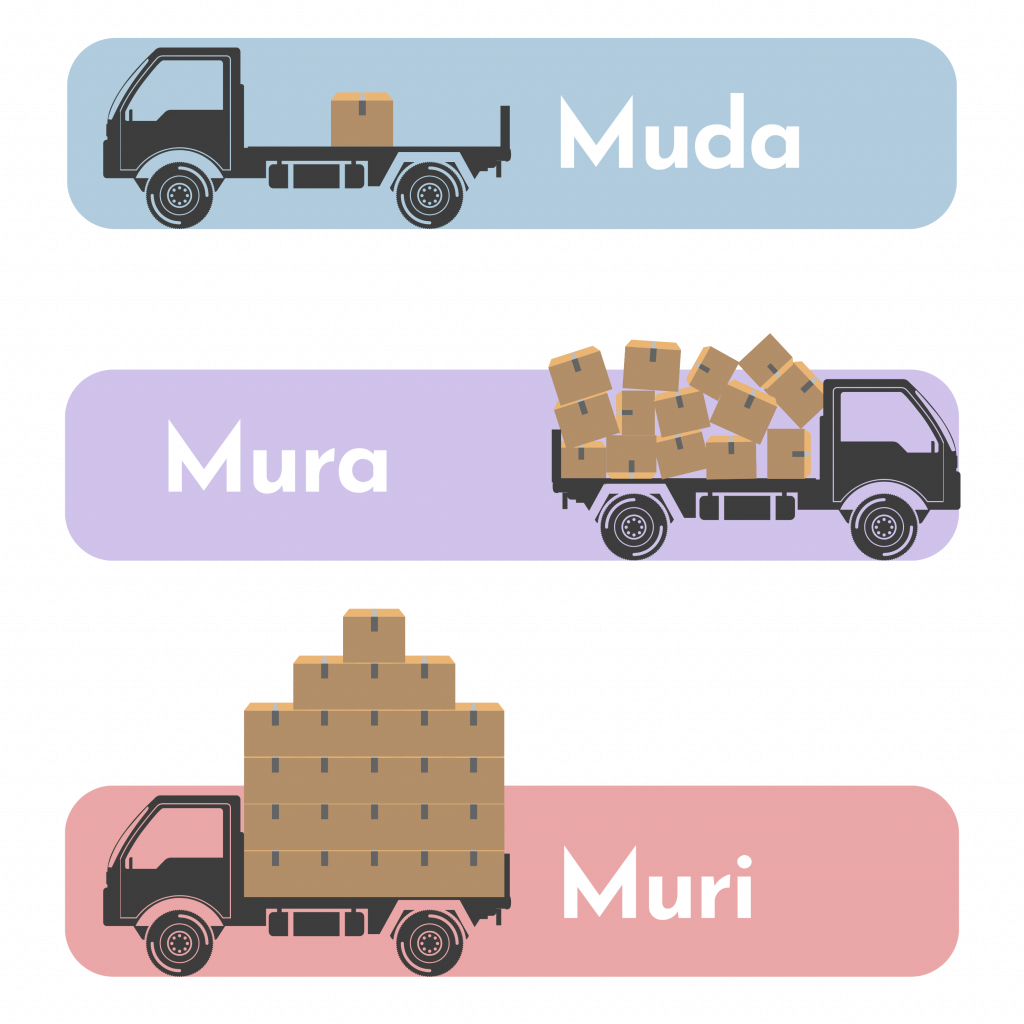

The Concept of Waste: Muda, Muri, Mura

Eliminating waste is fundamental to improving efficiency in lean manufacturing. There are three main types of waste:

- Muda (Waste): Any unnecessary activity that does not create value for the customer (overproduction, waiting, transportation, unnecessary processing, excess inventory, unnecessary motion, and defects).

- Mura (Inconsistency): Imbalances in production, inconsistent workload distribution, and flow problems in processes.

- Muri (Overburden): Overloading employees, machines, or processes beyond their capacity.

Toyota’s JIT System: Just-In-Time Production

One of the key components of the Toyota Production System is Just-In-Time (JIT) production. The core principle of JIT is to produce the right parts at the right time in the right quantity, minimizing inventory costs. This system was revolutionary in Toyota’s lean manufacturing approach and has been adopted by companies worldwide.

Benefits of JIT:

- Reduces inventory costs

- Speeds up production processes

- Eliminates waste (Muda)

- Enhances quality

Toyota developed strong collaboration and synchronization with suppliers to implement the JIT system effectively. The success of JIT is closely linked to the Kanban system.

In this section, we explored what lean manufacturing is, its history, the differences from mass production, and its core concepts. We particularly focused on the concept of waste and Toyota’s JIT system. In the next section, we will cover lean manufacturing techniques, ERP integration, real-life examples, and more.

Thank you for reading! Share your thoughts, experiences, or questions about lean manufacturing in the comments section. If you found this article helpful, consider sharing it on your social media to help more people discover lean manufacturing.