A few years ago, I visited a factory and observed workers racing against time on the production line. The strange thing was that sometimes they had to wait idly, while at other times they were working excessively hard. This inconsistency affected the entire production process. The management team was unhappy with productivity, employees were constantly stressed, and customer complaints were increasing. This is exactly where Lean Manufacturing comes into play!

With Lean Manufacturing, companies become more efficient with less waste, and employees can perform their jobs in a more organized and stress-free manner. Not only large corporations but also small and medium-sized enterprises (SMEs) can apply these principles to reduce costs, improve processes, and enhance customer satisfaction.

In this article, we will explore four key Lean Manufacturing principles, comparing them with traditional methods and illustrating them with real-life examples. Let’s dive in! 🚀

- Takt time: Align production with customer demand and avoid overproduction.

- One-piece flow: Ensure a continuous flow of products, reducing stock and waiting times.

- Standardized work: Establish clear processes to enhance quality and efficiency.

- Pull system: Plan production based on customer demand to prevent excess inventory and waste.

1. Takt Time: Adjust Production to Customer Demand

Takt time simply means producing at the speed your customer needs! If your customer places an order every 4 minutes, your production should match this rhythm. No more, no less!

Real-Life Example:

Recently, during a discussion with logistics company managers, I heard them complain: “Our deliveries are constantly delayed, yet we have too much stock!” ALPHA Trading applied takt time in their delivery processes, reducing delivery time by 25%. Previously, inconsistencies in stock management caused delays. However, with value stream mapping and route optimization, they improved efficiency and shortened delivery times.

Why Is It Important?

- Prevents unnecessary stock accumulation.

- Makes production more predictable.

- Allows for a quicker response to customer demand.

2. One-Piece Flow: Keep Production Moving!

Think about traffic: Is it faster to move in large groups, or does a smooth, continuous flow work better? One-piece flow ensures that products progress seamlessly and continuously through the production process, preventing bottlenecks and stockpile build-ups.

Real-Life Example:

A production manager once told me: “We manufacture in large batches, but machines keep stopping. This increases costs!” KazTek Invest implemented one-piece flow in their assembly lines, increasing production efficiency by 50%. Previously, producing in large batches led to stockpiles and late detection of defects. By applying SMED and Kaizen methodologies, they optimized their processes and established a smooth workflow.

Why Is It Important?

- Eliminates waiting times in production.

- Allows for early defect detection.

- Ensures faster delivery to customers.

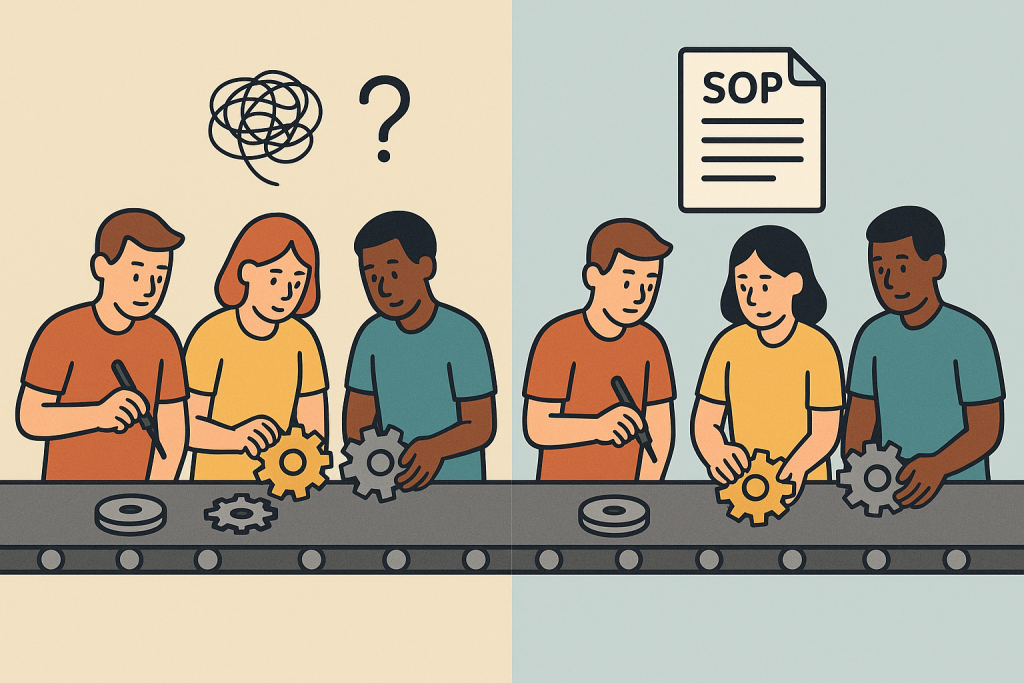

3. Standardized Work: Bring Stability to Your Processes

Imagine if two employees performed the same task in completely different ways. The result? Inconsistent quality, inefficient processes, and wasted time! Standardized work establishes clear and repeatable procedures, ensuring that quality and efficiency are maintained at all times.

Real-Life Example:

KazTek Invest introduced standard operating procedures (SOPs) in production, significantly improving workforce efficiency. Previously, every worker followed their own method, but after documenting standardized procedures, labor costs were reduced by 30% and production cycles became faster.

Why Is It Important?

- New employees can be trained faster.

- Ensures consistent product quality.

- Helps maintain sustainable processes.

4. Pull System: Plan Production Based on Demand

The pull system ensures that production happens only when there is actual customer demand. Instead of manufacturing excess stock ahead of time, you produce only what is needed, reducing inventory costs and waste.

Real-Life Example:

ALPHA Trading implemented a Kanban system, reducing their stock levels by 70%. Previously, they maintained high inventory levels, leading to unnecessary costs. With the Lean pull system, they now produce based on real orders, ensuring efficient stock management.

Why Is It Important?

- Reduces warehouse and storage costs.

- Makes production more flexible to demand changes.

- Eliminates overproduction, reducing financial burdens.

Conclusion: Start Implementing Lean Manufacturing in Your Business!

Now, a question for you: What types of waste exist in your business? Do you have excessive stock? Unnecessary waiting times? Inefficiencies in production?

By applying the Lean principles discussed in this article, you can start eliminating these issues:

- Use takt time to align production with customer demand.

- Apply one-piece flow to streamline processes.

- Implement standardized work to ensure consistency.

- Use the pull system to minimize inventory costs.

These small steps can lead to big improvements! Take the first step today and start applying Lean Manufacturing in your business! 🚀

Thanks for providing this information. The article gives a clear and practical overview of Lean principles, with helpful real-life examples that show how small changes can lead to major efficiency gains.