What is Kanban? The Key to Increasing Productivity in Businesses

In today’s competitive business environment, companies need continuous improvement methods to ensure sustainability and optimize costs. The Kanban system is an effective business management tool developed within the framework of lean production principles. So, what is Kanban, and how can it add value to your business? This article explores the fundamental principles, advantages, and implementation methods of Kanban. Additionally, we will present a case study of an SME in Kazakhstan that achieved significant improvements by implementing the Kanban system. This case study will help you better understand the tangible benefits of Kanban.

What is Kanban?

Kanban, meaning “visual card” in Japanese, is a system first developed by Toyota to visualize and manage the flow of materials and work processes in production and supply chains. It is based on the principles of a pull system to ensure that a business process produces the right quantity at the right time.

Initially implemented in Toyota’s production processes, this system has been widely adopted across various industries worldwide to enhance business workflows. However, establishing a Kanban system is not an end goal in itself. The real objective is to reduce waste and ensure the right parts are produced at the right time. This is achieved by visualizing workflows and limiting work-in-progress tasks.

The Advantages of Kanban for Businesses

The Kanban system provides businesses with the following key benefits:

- Prevents Overproduction: Kanban encourages production based on actual customer demand. While traditional production systems often rely on forecast-based manufacturing, Kanban focuses on real demand. Traditional systems typically involve large batch production and high inventory levels, whereas Kanban aims for small batch production and low inventory levels. This difference allows businesses to respond more quickly and reduce waste. Additionally, unlike the complexity of planning in traditional systems, Kanban offers a user-friendly process through visual control and simplified workflows, eliminating the risks of overproduction and excess inventory.

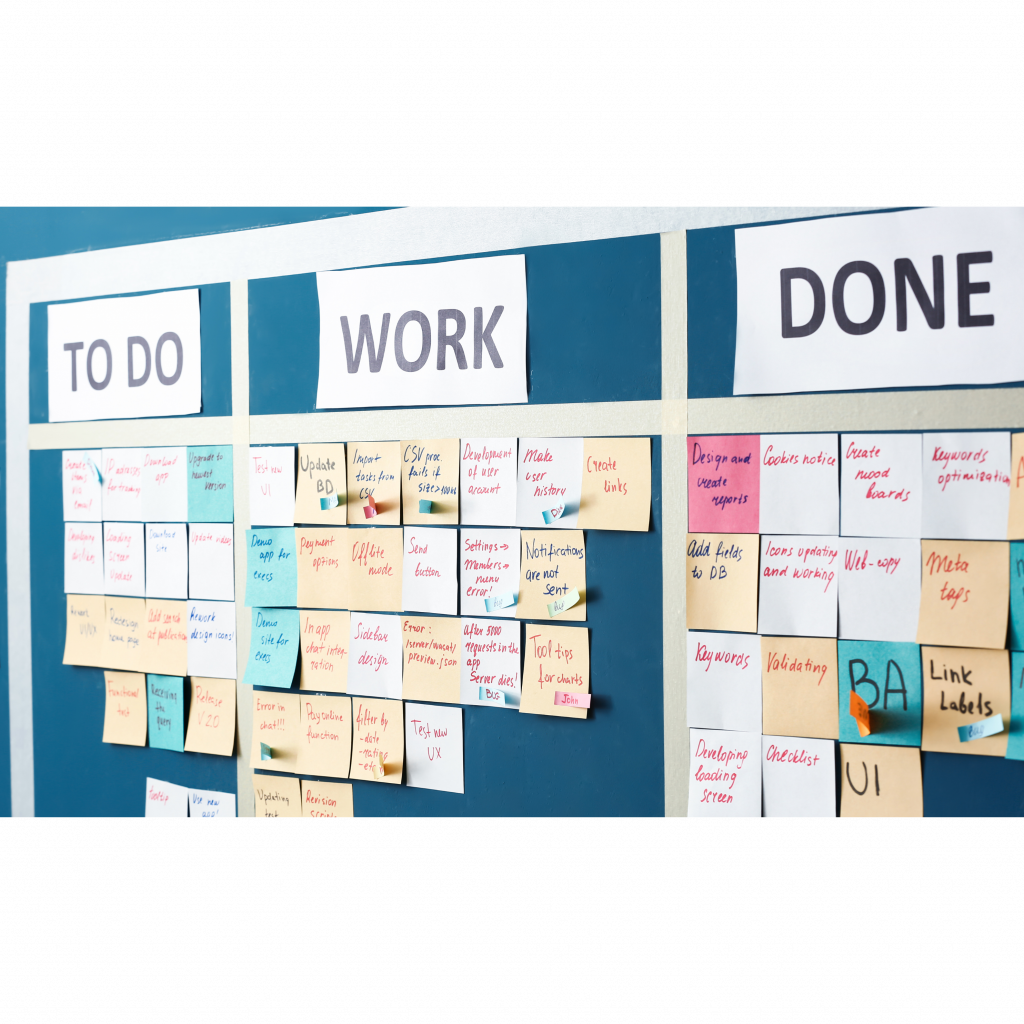

- Enables Visual Control: Kanban cards and boards allow for the visual tracking of workflow in production processes. This helps businesses quickly identify bottlenecks and issues within their processes.

- Provides Flexibility and Speed: Kanban allows businesses to respond swiftly to changing demands, giving them a more flexible and agile structure.

- Reduces Waste: Aligned with lean production principles, Kanban minimizes waste (muda), such as unnecessary movements, waiting times, and inventory accumulation.

- Enhances Employee Engagement: The Kanban system encourages employees to take a more active role in processes and fosters a culture of continuous improvement.

Types of Kanban

The Kanban system can be tailored to suit various business processes. Here are the most common types of Kanban:

1. Production Kanban

This type of Kanban specifies which product and how much of it should be produced within a production process, serving as a production order.

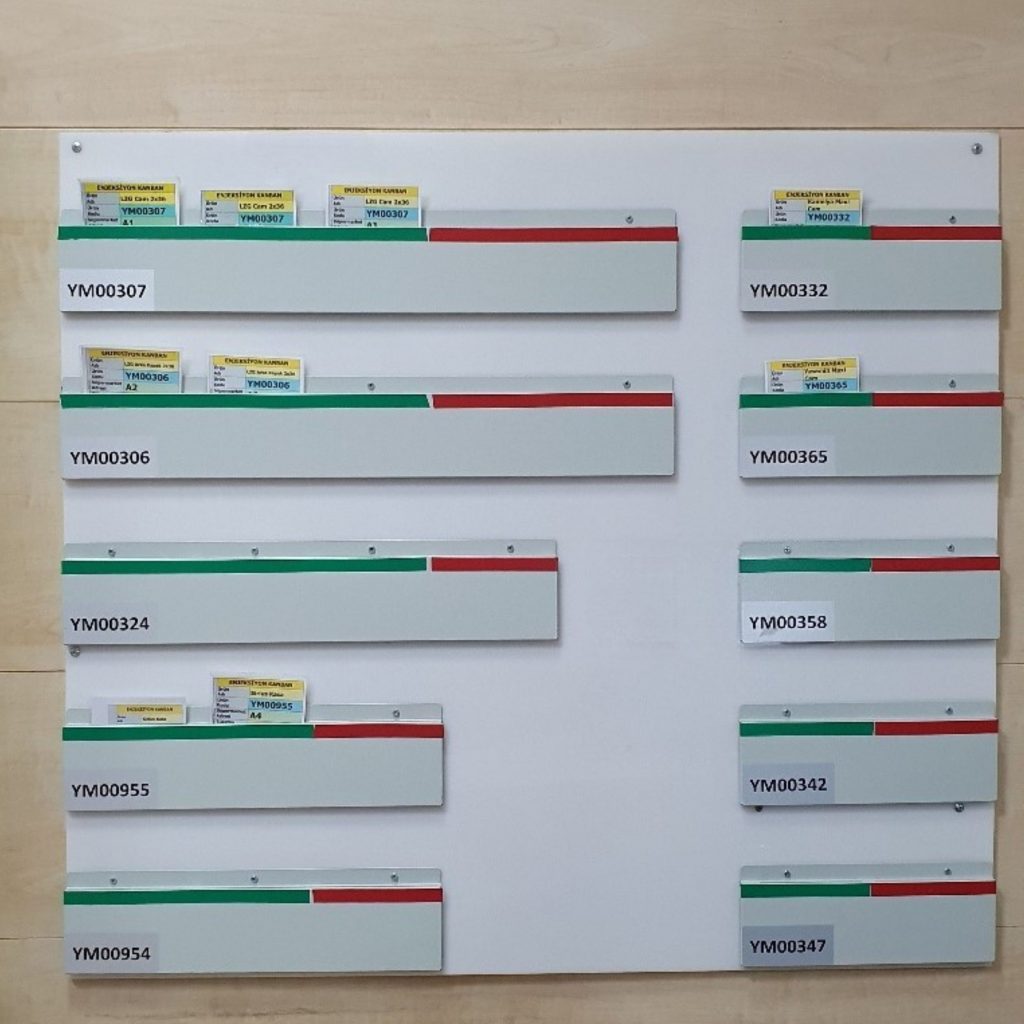

2. Withdrawal Kanban

Withdrawal Kanban defines the type and quantity of products that the customer process will withdraw from the supplier process.

3. Signal Kanban

Signal Kanban is particularly used in processes involving batch production. It includes signals that indicate when a production batch is nearing depletion.

4. Supplier Kanban

This type of Kanban regulates the flow of materials with supplier companies and establishes a two-way communication mechanism.

How to Implement a Kanban System?

To implement a Kanban system, businesses must fulfill certain prerequisites. However, some potential challenges may arise during this process, such as employee resistance, difficulties adapting to the new system, and the complexity of workflows. To overcome these barriers, companies need to train their employees and effectively communicate the benefits of the system. Additionally, starting with small and controlled pilot projects can demonstrate the impact of Kanban and build trust through successful outcomes. Visualizing processes and ensuring workload balance can also ease adaptation.

- Disciplined Work Environment: For Kanban to work effectively, standard work processes and balanced operator workloads must be established.

- Continuous Flow: Ensuring an uninterrupted flow in business processes is crucial, and Kanban serves as a tool to maintain this flow.

- Single-Piece Flow: Wherever possible, a single-piece flow system should be implemented, with Kanban used to ensure the continuity of the flow.

The Six Rules of Kanban and the KazTek Invest Case

To maximize the potential of Kanban in improving factory efficiency, the following six rules should be observed. Let’s examine how KazTek Invest applied these rules and overcame challenges:

1. Production should only be based on orders.

KazTek Invest optimized its production processes by focusing on customer demands. This prevented overproduction and inventory buildup. Production was initiated solely based on orders, reducing unnecessary production costs.

2. Work should only begin upon demand from the previous process.

Using the Withdrawal Kanban system, KazTek Invest enhanced the efficiency of its supply chain processes. This approach eliminated unnecessary material transfers between production cells and accelerated workflow.

3. Quality defects and errors should be resolved at their source.

The company strengthened quality control mechanisms in its production processes. Addressing quality issues at their source increased customer satisfaction and reduced error costs.

4. Limiting workflow increases process efficiency.

KazTek Invest visualized progress on Kanban boards and limited workloads. This enabled quick identification and resolution of bottlenecks.

5. Visual tools help quickly identify bottlenecks and issues.

The company actively used visual management tools to monitor and continuously improve production processes.

6. Work progress on the Kanban board should be monitored continuously.

KazTek Invest’s managers regularly monitored Kanban boards to identify delays and issues in the workflow. This ensured rapid resolution of process disruptions.

Case Study: The Transformation Journey of KazTek Invest with Lean Production

Kazakhstan’s leading lighting company, KazTek Invest, embraced lean production principles, implementing profound changes in its business processes and achieving significant gains. While struggling with challenges such as high inventory levels, long delivery times, and low efficiency, the company overcame these issues through lean production and significantly enhanced its competitiveness.

Conclusion

The Kanban system is an effective tool that enables businesses to enhance their efficiency and reduce costs in line with lean production and continuous improvement principles. By implementing Kanban in your business, you can prevent overproduction, reduce waste in processes, and respond to customer demands more quickly.

For more information on Kanban and to implement the Kanban system in your business, contact Lean Solutions consultancy services!