What is Waste and How to Eliminate It? A Lean Transformation Guide

The concept of “waste,” often heard in the business world, is a fundamental principle of lean transformation. The primary goal of lean is to eliminate all activities that do not create value, ensuring maximum efficiency and effectiveness. But what exactly is waste, and how is it addressed within the lean framework?

What is Waste in Lean?

I once witnessed a factory where workers constantly collected scrap materials and piled them in a corner. When I asked, “Where does all this scrap come from?” no one could provide a clear answer. This scenario serves as a perfect example of how waste is addressed in lean thinking. Waste refers to any activity that does not add value and is meaningless from the customer’s perspective.

In lean transformation literature, waste is defined as anything that does not contribute to the product or service’s value. In other words, any activity that fails to create customer-perceived value is considered waste.

Types of Waste

Successful case studies can illustrate the impact of waste on businesses. For example, imagine a furniture manufacturer struggling with excessive inventory and how they overcame this challenge through lean transformation. Such examples not only provide theoretical knowledge but also practical inspiration. Consider a small business facing financial difficulties due to excess stock, only to solve the problem through lean practices.

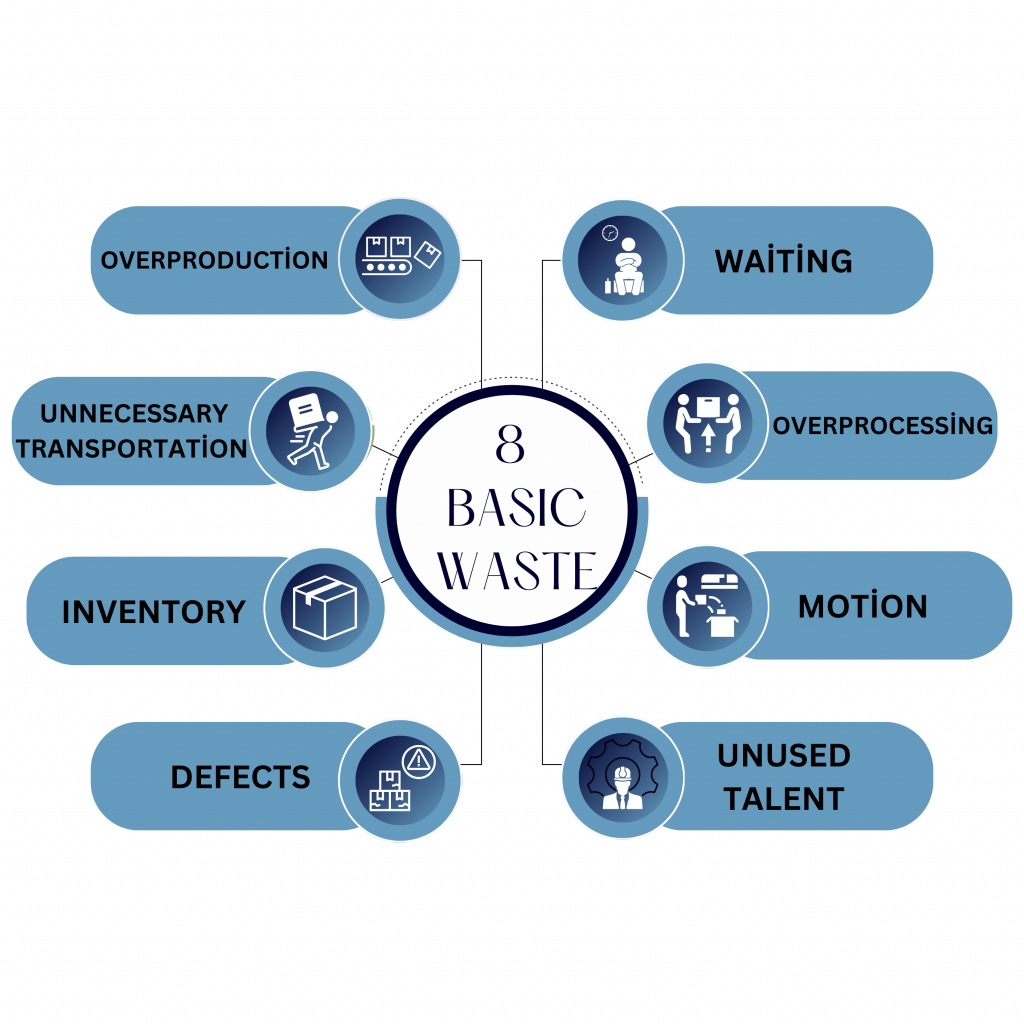

In lean methodology, the Toyota Production System introduces a classification commonly referred to as the “7 Wastes,” with an eighth type of waste later added:

- Overproduction: Producing more or earlier than required.

- Example: In a food factory, overproduction can lead to expired inventory, increasing costs.

- Waiting: Materials, information, or workers waiting for the next step.

- Example: Hotel guests waiting during check-in can lead to dissatisfaction and negative reviews.

- Example: Hotel guests waiting during check-in can lead to dissatisfaction and negative reviews.

- Unnecessary Transportation: Moving products or materials without purpose.

- Example: Repeatedly moving materials within a warehouse wastes time and energy.

- Example: Repeatedly moving materials within a warehouse wastes time and energy.

- Overprocessing: Performing unnecessary extra steps.

- Example: Polishing a product excessively adds no value to the customer but increases costs.

- Example: Polishing a product excessively adds no value to the customer but increases costs.

- Inventory: Holding excess raw materials, work-in-progress, or finished goods.

- Example: Excess inventory in an automotive factory can reduce workspace and increase storage costs.

- Example: Excess inventory in an automotive factory can reduce workspace and increase storage costs.

- Motion: Unnecessary physical movements by workers.

- Example: Workers frequently searching for tools on a production line wastes time.

- Example: Workers frequently searching for tools on a production line wastes time.

- Defects: Errors requiring rework or resulting in scrap.

- Example: Incorrectly cut fabric in the textile industry increases rework costs.

- Unused Talent: Failing to leverage employees’ skills, knowledge, and creativity.

- Example: Ignoring software developers’ suggestions in a tech company can miss opportunities for innovation.

How Can We Identify Waste?

The detailed use of lean tools is critical in this process. For instance:

- 5S: Organizing the workplace to prevent unnecessary movements and time waste.

- Kanban: Controlling overproduction and inventory through a pull system.

- Poka-Yoke: Implementing simple yet effective error-prevention methods to enhance quality and reduce rework costs.

Identifying and eliminating waste plays a crucial role in achieving lean success. The following steps can be taken:

- Gemba Walks: Observing work processes on-site under real conditions.

- Value Stream Mapping: Analyzing each step in the value creation process.

- Kaizen Events: Conducting process improvement activities.

The Cost of Waste: Overlooked Economic and Psychological Burdens

Waste doesn’t just impact financial costs; it also takes a toll on employees’ motivation and job satisfaction. Imagine your colleagues getting frustrated by recurring errors or feeling demoralized by long waiting times. This is why addressing waste involves not only numbers but also its effects on people.

For instance, repetitive mistakes can lower morale and lead to disengagement among employees, negatively affecting productivity and job satisfaction. Waste isn’t just about lost time and resources; it directly translates into tangible costs, such as:

- Defective Production: Reworking or scrapping defective products leads to lost time and material waste. Example: Incorrectly cut metal parts require reprocessing, increasing operational costs.

- Excess Inventory: Holding surplus stock ties up capital and disrupts cash flow. Example: In retail, unsold products may need to be discounted or discarded, reducing profitability.

- Waiting: Delays in production lines leave machines and workers idle, reducing efficiency. Example: A production process halts due to missing materials, increasing operational costs.

The Benefits of Eliminating Waste: Succeeding Together

Through lean thinking, your company can adopt a business model that’s mindful of both the environment and employees. Imagine reducing energy consumption to cut costs while contributing to environmental conservation—and motivating your team by valuing their ideas. That’s the true power of lean!

Lean thinking aligns closely with sustainability goals:

- Waste Reduction: Preventing unnecessary material use minimizes environmental impact.

- Energy Efficiency: Systems and processes that consume less energy reduce costs while promoting environmental awareness.

- Sustainable Business Models: Lean practices enhance long-term resilience and corporate responsibility.

- Cost Savings: Eliminating unnecessary activities ensures more effective use of resources.

- Time Savings: Removing delays and redundant steps accelerates work processes.

- Improved Quality: Reducing errors enhances the quality of products and services.

- Environmental Benefits: Lower energy consumption and waste result in more sustainable operations.

Employee Engagement: The Key to Strengthening Lean Culture

Active participation from employees is essential for successful lean transformation. Gathering employee insights, involving them in process improvements, and recognizing their contributions help establish and reinforce a lean culture. For example:

- Process Improvements: Operators on a production line reporting daily workflow issues enable quick fixes and improvements.

- Innovative Solutions: Employees in direct customer contact in service industries can offer feedback to enhance customer experiences.

- Recognition and Motivation: Rewarding employee contributions boosts morale and encourages continuous improvement.

Looking Ahead: Lean Thinking and Digital Transformation

Combining lean thinking with digital transformation can create broader impacts through sector-specific applications:

- Healthcare: IoT devices can reduce waiting times in patient monitoring processes.

- Service Sector: AI-based systems can analyze customer feedback to eliminate redundant tasks.

- IT: Automation software minimizes unnecessary movements and repetitive manual work.

When lean thinking merges with digital transformation, its impact becomes even more profound. Future production systems can manage waste more effectively using tools like data analytics, AI, and automation. For example:

- Real-Time Tracking with IoT: IoT technology enables real-time monitoring of inventory levels, machine performance, and process flows, quickly identifying waste points.

- AI-Powered Planning: Artificial intelligence improves demand forecasting, preventing overproduction and inventory waste.

- Autonomous Systems: Robotics and autonomous systems minimize unnecessary movements and handling, optimizing workflows.

The success of lean transformation in the future will increasingly depend on such technological integrations. By combining digitalization with lean thinking, businesses can improve resource efficiency and create more sustainable models.

Conclusion

Eliminating waste, a cornerstone of lean transformation, does more than cut costs; it strengthens your organization’s competitive edge. By identifying and systematically addressing potential waste, you can build a more efficient, effective, and value-driven organization.