Lean projects without value stream-based organization fail to maintain the initial excitement. In this article I explain why and how to fix it. I have witnessed many projects related to lean transformation. You know the initial excitement; kaizen workshops are established, teams are motivated, measurements are made. The place is filled with energy for a […]

A few years ago, I visited a factory and observed workers racing against time on the production line. The strange thing was that sometimes they had to wait idly, while at other times they were working excessively hard. This inconsistency affected the entire production process. The management team was unhappy with productivity, employees were constantly […]

BEGINNING: RECOGNIZING THE NEED FOR CHANGE In July 2023, SAG Gılamları embarked on a lean transformation journey to gain deeper insights into the challenges faced in production efficiency and to develop lasting solutions. This decision was driven not only by the need for operational improvements but also by the desire for a mindset shift. The […]

2022… It was the beginning of a challenging year for AYVEN Group. Our warehouses were overflowing, customers constantly complained about delayed orders, and our operations were becoming increasingly costly. To be honest, even we didn’t know where we were heading. That’s when we came across the concept of lean transformation. At first, we wondered, “Does […]

Lean Production Techniques and Application Examples In the first part, we looked at the basics of lean production and Toyota’s JIT system. Now let’s take a closer look at lean production techniques, ERP integration, real-life examples and other important topics. Lean Production Techniques: SMED, Poka-Yoke and Kaizen Lean manufacturing involves many techniques and methods to […]

In today’s competitive business world, companies need to increase efficiency, reduce costs and increase productivity. This is exactly where Lean Manufacturing comes into play. This powerful method, which enables companies to gain a competitive advantage by optimizing production processes and eliminating waste, offers great opportunities, especially for production managers and engineers: Creating more value with […]

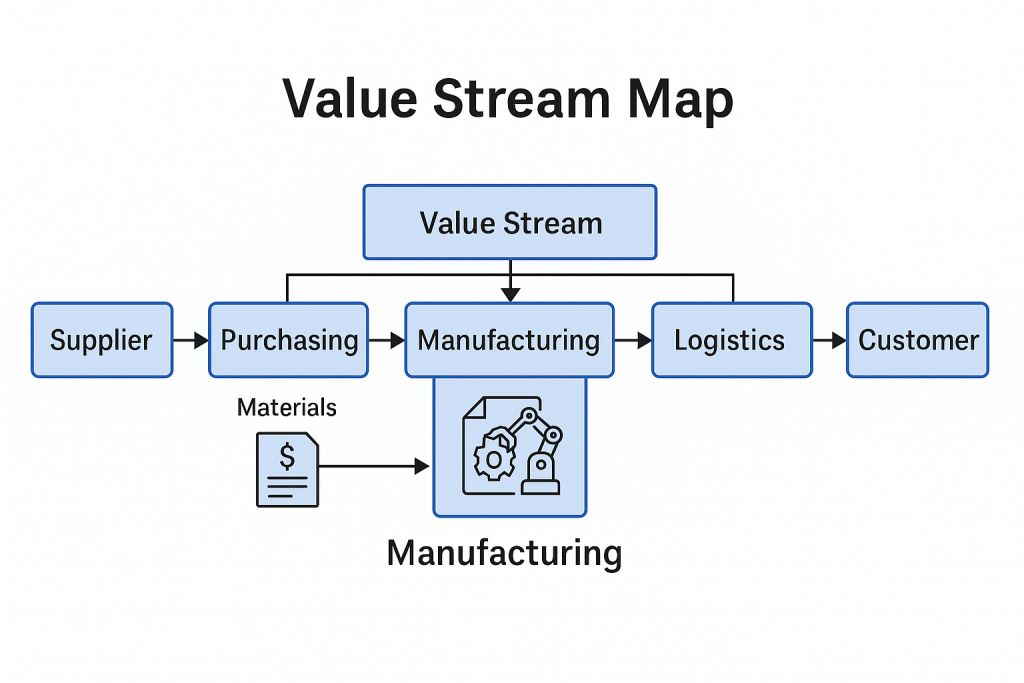

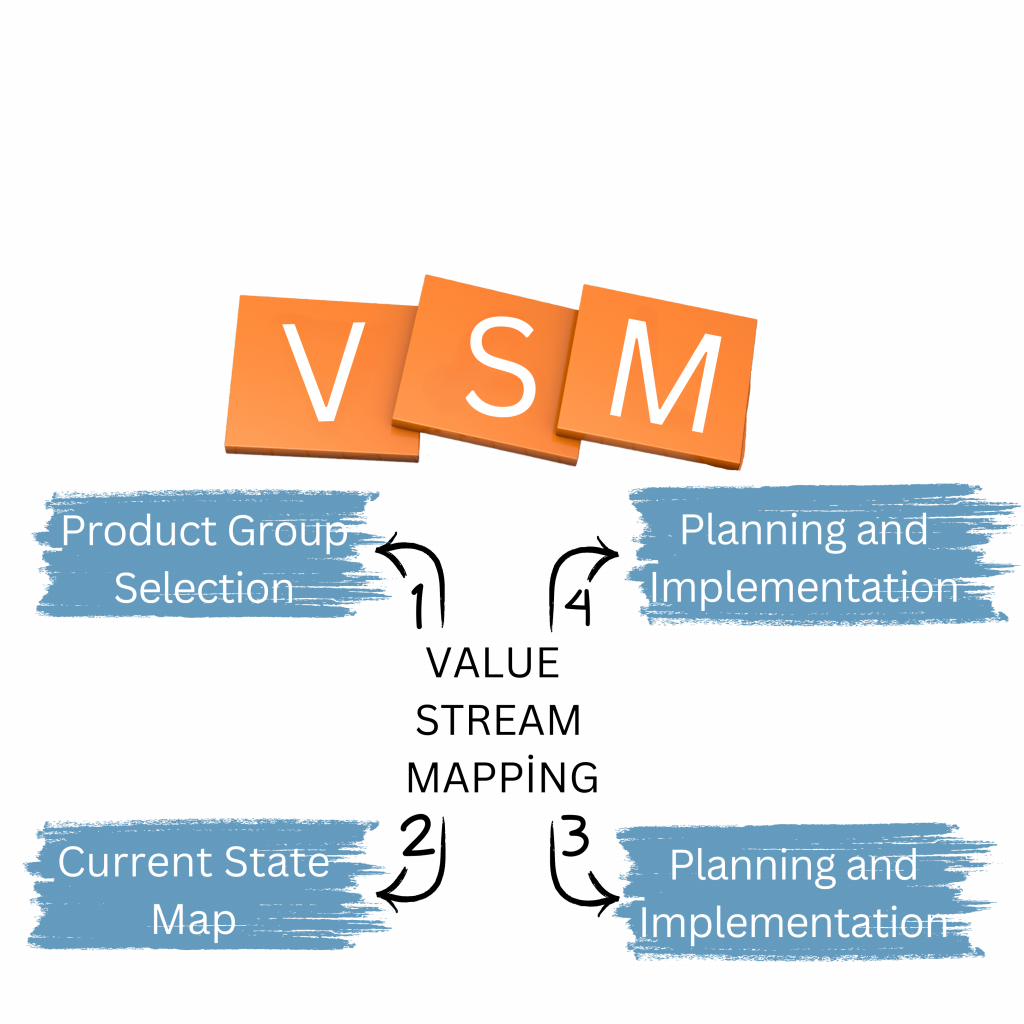

What is VSM? The Power of Visualizing Business Processes In today’s fast-paced and competitive world, constant improvement is a necessity. But are you sure your company is unlocking its full potential? This is where Value Stream Mapping (VSM) comes in, sharpening your ability to “see” your business processes. So, what exactly is VSM? Let’s dive […]

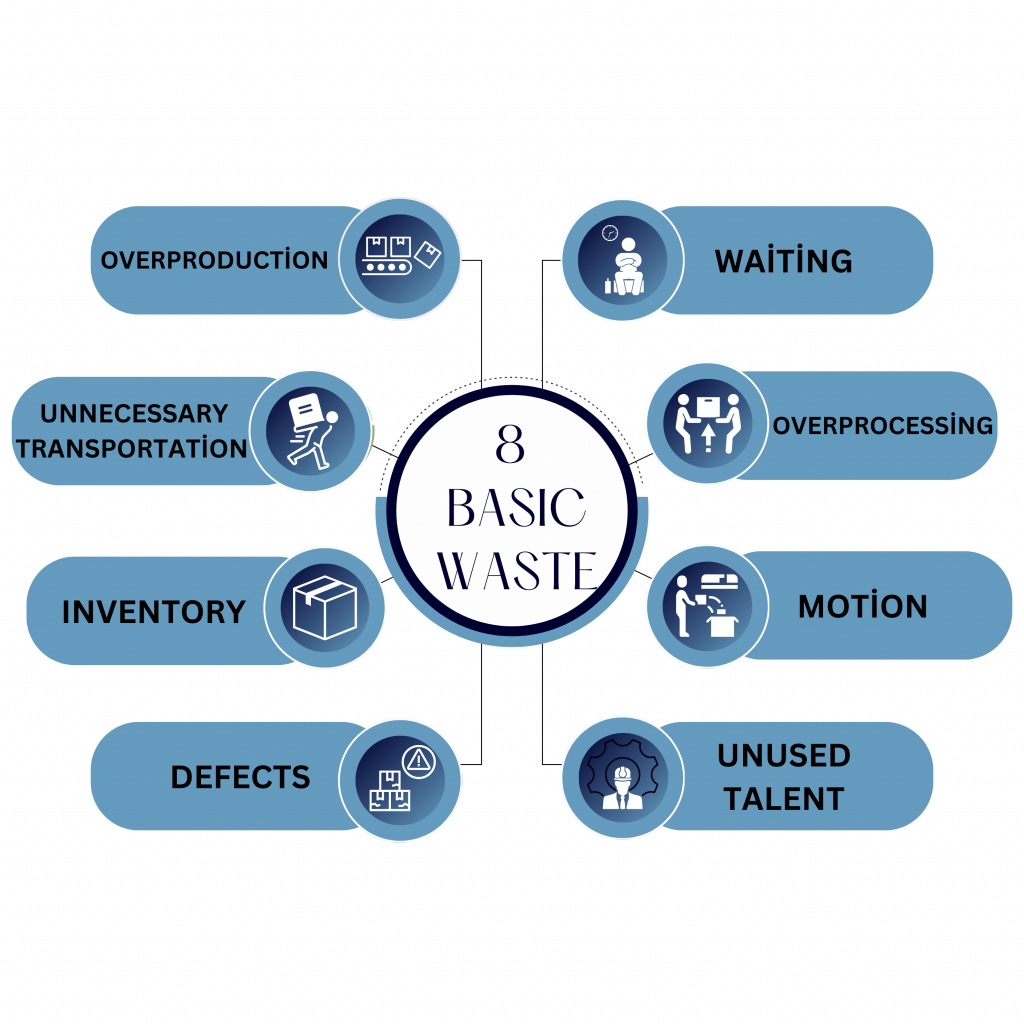

What is Waste and How to Eliminate It? A Lean Transformation Guide The concept of “waste,” often heard in the business world, is a fundamental principle of lean transformation. The primary goal of lean is to eliminate all activities that do not create value, ensuring maximum efficiency and effectiveness. But what exactly is waste, and […]

What is Kanban? The Key to Increasing Productivity in Businesses In today’s competitive business environment, companies need continuous improvement methods to ensure sustainability and optimize costs. The Kanban system is an effective business management tool developed within the framework of lean production principles. So, what is Kanban, and how can it add value to your […]

What is Gemba? A Journey to the Heart of Business Processes In the business world, many methods are employed to enhance efficiency and optimize processes. However, these methods often rely on desk-based planning and implementation rather than observing the actual processes. True improvements happen on-site, where work is performed and processes are observed. This is […]

- 1

- 2